Hidden cracks, hot spots, and PID effects are three important factors that affect the performance of photovoltaic modules and have recently attracted attention from everyone. Today, I will explain to you about hidden cracks.

What is' hidden crack '?

Cracking is a defect in battery cells.

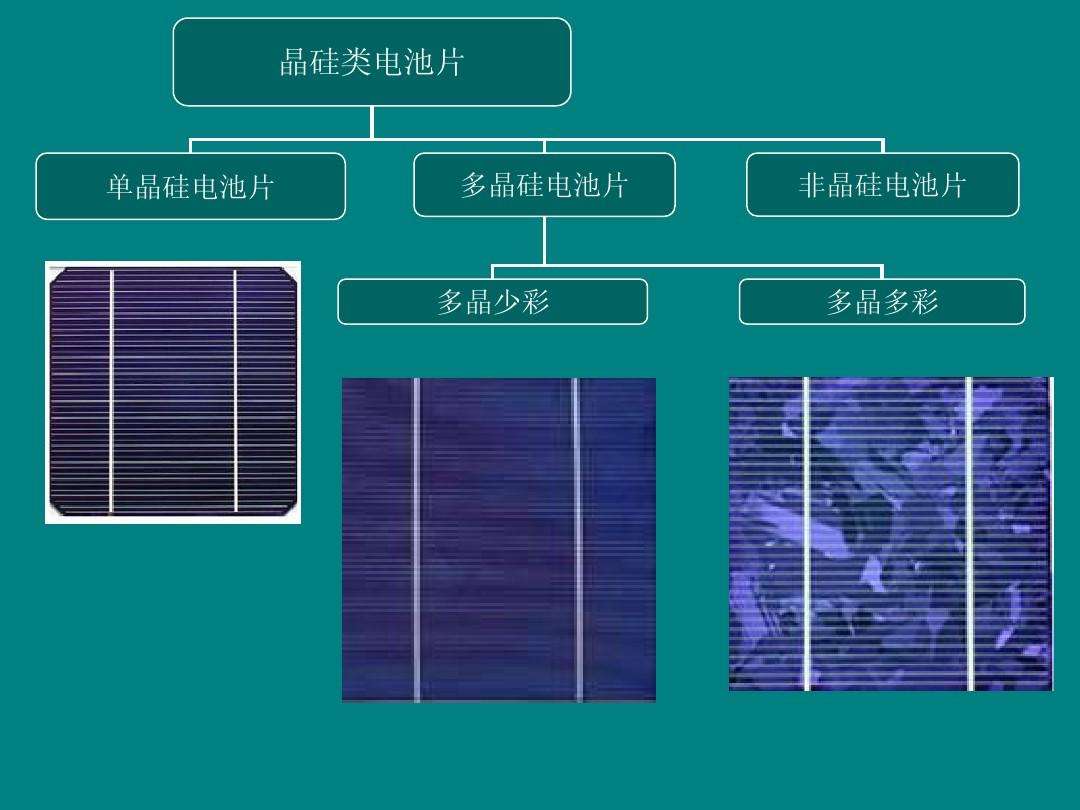

Due to the inherent characteristics of crystal structure, crystalline silicon battery cells are very prone to cracking. The production process of crystalline silicon modules is long, and many links may cause hidden cracks in the battery chip (according to Mr. Yang Hong of Xi'an Jiaotong University, there are about 200 reasons in the battery production stage alone). The essential reason for the occurrence of hidden cracks can be summarized as the mechanical or thermal stress generated on the silicon wafer.

In recent years, crystalline silicon component manufacturers have been developing towards thinner and thinner crystalline silicon battery cells in order to reduce costs, thereby reducing the ability of battery cells to prevent mechanical damage. The three component EL detector can effectively detect hidden crack problems, helping you save costs.

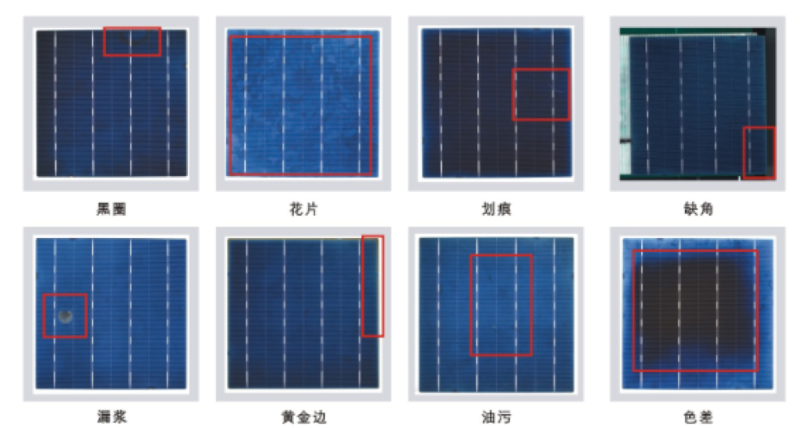

In 2011, ISFH in Germany released their research results: According to the shape of hidden cracks in battery cells, they can be divided into five categories: tree shaped cracks, comprehensive cracks, oblique cracks, cracks parallel to the main grid line, cracks perpendicular to the grid line, and cracks that run through the entire battery cell.

Figure 2: Crystal silicon cell structure

According to the structure of crystalline silicon batteries, as shown in the figure above, the current generated by the battery cells relies on the collection and export of "main grid lines on the surface and fine grid lines perpendicular to the main grid lines". When hidden cracks cause the fine grid line to break, the fine grid line cannot transport the collected current to the main grid line, which will cause partial or even complete failure of the battery cells.

Based on the above reasons, the hidden cracks parallel to the main grid line (Class 4) have the greatest impact on the function of the battery cells. According to the research results, 50% of the failure pieces come from hidden cracks parallel to the main gate line.

The efficiency loss of a 45 ° inclined crack (type 3) is 1/4 of the loss parallel to the main grid line.

Cracks perpendicular to the main grid line (type 5) hardly affect the fine grid line, so the area of battery cell failure is almost zero.

Compared to the grid lines on the surface of crystalline silicon batteries, the overall surface of thin film batteries is covered with a transparent conductive film, which is also one of the reasons why thin film components have no hidden cracks.

Research results have shown that when the failure area of a single battery cell in a component is within 8%, it has little effect on the power of the component, and 2/3 of the diagonal stripes in the component have no effect on the power stability of the component. Therefore, when the battery cells in the component experience hidden cracks, efficiency loss may occur, but there is no need to talk about the "color change" of hidden cracks.

3. Means of detecting 'hidden cracks'

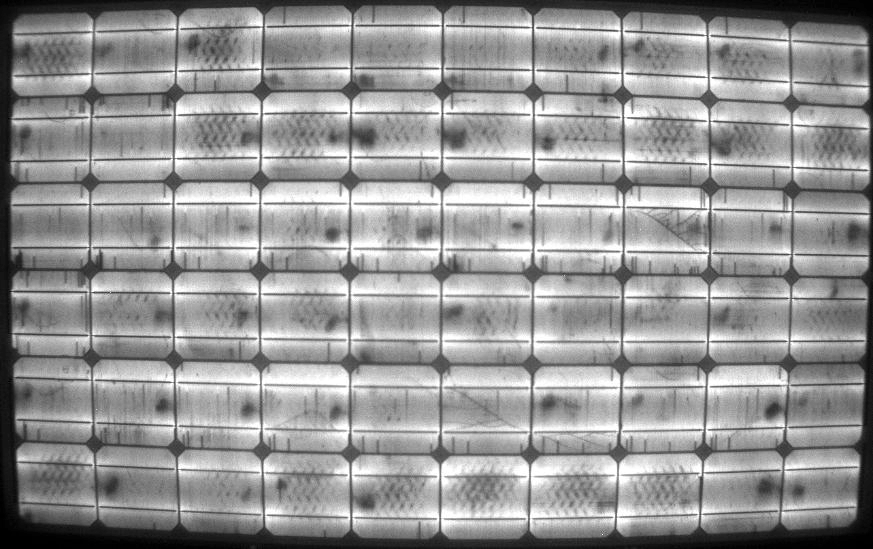

EL (Electroluminescence) is a simple and effective method for detecting hidden cracks. The detection principle is as follows.

The core part of the battery cell is a semiconductor PN junction, which is in a dynamic equilibrium state internally without other excitation conditions such as light, voltage, and temperature. The number of electrons and holes remains relatively stable.

If a voltage is applied, the internal electric field in the semiconductor will be weakened, and electrons in the N region will be pushed towards the P region, recombining with holes in the P region (which can also be understood as holes in the P region being pushed towards the N region, recombining with electrons in the N region). After recombining, they will be emitted in the form of light, resulting in electroluminescence.

When the forward bias voltage is applied, the crystalline silicon battery will emit light with a wavelength of about 1100nm, which belongs to the infrared band and cannot be observed by the naked eye. Therefore, during EL testing, it is necessary to use a CCD camera to assist in capturing these photons, and then display them in the form of images after computer processing. The three component EL detector can effectively detect hidden crack problems, helping you save costs.

After applying voltage to the crystalline silicon module, the more electrons and holes are excited to recombine, the more photons are emitted, and the measured EL image becomes brighter; If the EL image in some areas is relatively dark, it indicates that there are fewer electrons and holes generated in that area (such as in the middle of the battery in Figure 3), indicating the presence of defects (recombination centers) in that area; If some areas are completely dark, it means that there is no recombination of electrons and holes (marked by the red line in Figures 3 and 4), or the light emitted is obstructed by other obstacles (at the main gate line in Figures 3 and 4), and the signal cannot be detected.

Figure 5 Normal Component EL Image

4 Summary

1) There are various types of hidden cracks, and not all of them will affect the performance of battery cells;

2) In the process of component production, transportation, installation, and maintenance, taking into account the easy cracking characteristics of crystalline silicon components, it is necessary to improve and refine the operation process in each process section, transportation, and construction process to reduce the possibility of component hidden cracks.

3) EL is a simple and effective method for detecting hidden cracks.