Machine vision light is part of machine vision imaging, and in machine vision, light sources mainly play the following roles:

1. Illuminate the target and improve brightness formation; Favorable effect for image processing

2. Overcoming ambient light interference and ensuring image stability; Used as a measuring tool or reference.

3. By designing appropriate lighting sources, the target information and background information in the image can be best separated, greatly reducing the difficulty of image processing algorithm segmentation and recognition,

4. Simultaneously improve the positioning and measurement accuracy of the system, thereby improving its reliability and comprehensive performance. On the contrary.

If the selection and design of the light source are not appropriate, it may lead to inadequate results in the design of image processing algorithms and imaging systems. Therefore, the success or failure of light source and optical system design is the primary factor determining the success or failure of the visual system.

In machine vision systems, the target information of the tested object can be distinguished from the background information through appropriate lighting, in order to obtain high-quality and high contrast images, thereby reducing the difficulty of image processing algorithms and improving the accuracy and reliability of the system.

In practical projects, the imaging effect of images is closely related to the lighting conditions. It is no exaggeration to say that it can directly affect the quality and application effectiveness of input data.

Good lighting conditions can achieve good imaging results, effectively distinguishing objects from the background and reducing the difficulty of recognition.

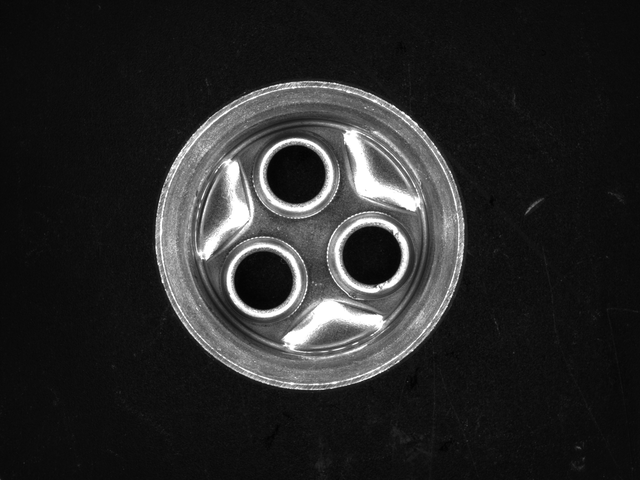

As shown in the figure:

Circular light : Provides direct illumination of different angles and color combinations on the tested object, highlighting the three-dimensional information of the object, avoiding the phenomenon of shadow illumination at angles, highlighting imaging features, and can be used in conjunction with a diffuser to make the light more uniform and soft, expanding the heat dissipation area, and improving the heat dissipation performance of the light source. Application field: PCB substrate detection; Plastic container testing; Electronic component testing; Integrated circuit character detection; Semiconductor product appearance character detection; Product packaging appearance and label inspection; Damaged pills and lack of testing; Spherical object illumination; Component pin positioning.

Point light : high-power LED, small size, high luminous intensity; An alternative to fiber optic halogen lamps, especially suitable as coaxial light sources for lenses; Efficient heat dissipation device, greatly improving the service life of the light source. Application field: for chip detection; Mark point positioning; Wafer and liquid crystal glass substrate correction; Image scanning.

Square light : LED illumination can form a large square field of view, and the measured object is evenly diffused and illuminated at low angles through a light guide plate. Different working distances can create different lighting environments, which can be used for different detection types. Application field: Surface collision, scratch and other defect detection; Printing characters, fingerprints, and graphic recognition.

Strip light : Adopting high-strength LED array. The preferred option for large area lighting is to freely combine and provide illumination to the surface of objects from multiple angles. Application case: IC component detection; Welding inspection; Glass based component testing; Connector inspection; Plane defect detection.

Coaxial light : The good directionality of coaxial light source can eliminate shadows caused by uneven surface of objects, thereby reducing interference, suitable for high working distances and obvious image features; High density LED arrangement, scientific heat dissipation design, and partial use of spectroscopic design to reduce light loss, improve imaging clarity, and evenly illuminate the surface of objects. For surface detection of reflective workpieces, it can highlight surface detection. Application field: The series of light sources are most suitable for scratch detection of highly reflective objects such as metals, glass, film, chips, etc., damage detection of chips and silicon chips, Mark point positioning, and packaging barcode recognition.

AOI light : By illuminating with multiple colors and angles, highlight the three-dimensional information of the product surface; Add a diffuser to guide light and reduce reflection; Combination of different angles; Application field: Used for soldering detection of circuit boards.

Surface light : high-density LED array layout, providing high intensity uniform diffuse light irradiation. Maximize the effective usage area of the luminous surface, suitable for use in compact environments. Flexible installation method. Application field: Dimensional measurement of mechanical parts; Electronic components; Appearance inspection of IC; Film stain detection.

In addition, we also need to consider the following points when selecting a light source:

1. Clear contrast and clear boundary between the target and background

2. The overall brightness is uniform, and the overall uneven grayscale difference affects image processing

3. The background should be as light and uniform as possible, without interfering with image processing

4. Realistic colors, moderate brightness, and no overexposure

5. Infrared light has a long wavelength and strong penetrability. Infrared light can filter out the interference of organic coatings on the surface of the product, detect surface scratches, and also penetrate dark oral liquid to detect internal impurities.

The length of ultraviolet light wave, with high diffusion rate and excitation fluorescence characteristics, is suitable for locating Mark points on the surface of transparent objects; Router character detection shows that the ink has a low reflectivity for short wavelength ultraviolet light; UV colloid detection; Stealth code reading, etc.

6. Complementary colors: Symmetric colors in the color ring are superimposed on black and white cameras to present a dark color

Adjacent color: In the color ring, adjacent or the same color is superimposed on a black and white camera to present a light color

7. In addition, different materials of metals have different reflectivity of light sources in different wavelengths; Copper and gold have weaker reflection for light sources with short wavelengths; Silver and aluminum have the greatest difference in reflection at wavelengths around 850nm; Blue light source can better distinguish between copper, gold, and aluminum

Through these understanding and analysis, we should have a basic understanding of how to choose a light source. If we still don't understand, we can try the following two methods:

1. Observation test method (most commonly used)

Try using different types of light sources to illuminate objects at different positions, and then observe the image through a camera

2. Scientific analysis method (the most effective)

Analyze the imaging environment and recommend the best solution.

The test samples should be rich, with different types of intact samples and problematic samples. Try to avoid all problems with the sample as much as possible, especially with the most difficult to detect samples with actual problems.

There are multiple backup test light sources, several common categories of LED light sources, and different colors are required.

Analyze the operating environment of the system, understand the requirements for system structure and operation from the customer, and determine the spatial structure relationship of the camera, light source, and measured object.