What is photovoltaic module cracking?

Hidden cracks refer to hidden cracks that may occur in battery cells that are not easily visible to the naked eye when battery cells (components) are subjected to significant mechanical or thermal stress.

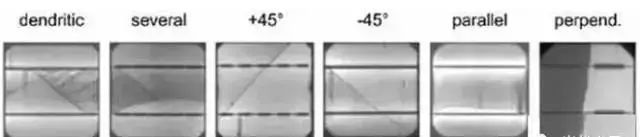

According to the shape of hidden cracks in battery cells, they can be divided into 5 types: tree shaped cracks, comprehensive cracks, oblique cracks, cracks parallel to the main grid line, cracks perpendicular to the grid line, and cracks that run through the entire battery cell.

The influence of cracking on photovoltaic modules

The current generated by the battery cells relies on the collection and export of "main grid lines on the surface and fine grid lines perpendicular to the main grid lines". When hidden cracks cause the fine grid line to break, the fine grid line cannot transport the collected current to the main grid line, which will cause partial or even complete failure of the battery cells.

Based on the above reasons, we can see that the biggest impact on the function of the battery cell is the hidden crack parallel to the main grid line. According to the research results, 50% of the failure pieces come from hidden cracks parallel to the main gate line.

The efficiency loss of a 45 ° inclined crack is 1/4 of the loss parallel to the main grid line.

The cracks perpendicular to the main grid line hardly affect the fine grid line, so the area of battery failure is almost zero.

Compared to the grid lines on the surface of crystalline silicon batteries, the overall surface of thin film batteries is covered with a transparent conductive film, which is also one of the reasons why thin film components have no hidden cracks.

Research has shown that severe component cracking can lead to a loss of component power, but the magnitude of the loss may not be certain. Cracks have little impact on the electrical performance of components, while cracks have a significant impact on the power loss of components; Aging test, which means that changes in temperature and humidity of the component under working or non working conditions may exacerbate the cracking of the battery cells; The anti aging ability of the cell without cracks in the module is stronger than that of the cell with cracks.